Foshan Happy Technology has once again demonstrated its engineering and manufacturing expertise by delivering a fully customized vertical spraying production line to Hunan Jinniu Aluminium Co., Ltd. This project reflects our commitment to providing tailored, high-performance aluminium profile coating equipment that meets the exact requirements of our clients in the aluminium extrusion and finishing industry.

Hunan Jinniu Aluminium is a well-established enterprise specializing in high-quality aluminium profiles for architectural and industrial applications. As the company expanded production capacity, it sought a modern industrial spraying system capable of enhancing surface finish quality, optimizing space usage, and ensuring consistent, automated production.

About the Client: Hunan Jinniu Aluminium Co., Ltd.

Located in Hunan Province, Jinniu Aluminium has built a reputation for producing reliable and aesthetically appealing aluminium products, ranging from window and door profiles to custom extrusions for industrial applications. With a strong focus on both domestic and international markets, the company needed a coating solution that could match its ambitions for quality and efficiency.

The exterior of Hunan Jinniu Aluminium’s facility in Hunan Province.

Project Requirements

The client approached Foshan Happy Technology with the following key requirements:

1. Space Efficiency – The available factory floor space needed to be maximized, making a vertical spraying production line the most suitable choice.

2. High Throughput – The line should handle large daily production volumes without compromising coating uniformity.

3. Surface Quality – Achieve a flawless, durable finish on all aluminium profiles, suitable for both powder coating and specialized surface treatments.

4. Automation – Reduce manual handling to improve consistency, safety, and labor efficiency.

5. Energy Efficiency – Incorporate advanced curing systems and ventilation to minimize energy consumption and VOC emissions.

Our Engineering Solution

After a thorough site survey and discussions with Jinniu Aluminium’s production team, our engineers proposed a custom powder coating line based on a vertical conveyor system. This design included:

Automated Profile Loading Station – Reducing manual lifting and risk of damage.

Multi-Stage Pre-Treatment – Chemical cleaning, rinsing, and drying stations to ensure optimal adhesion.

Precision Powder Spraying Booths – Equipped with high-efficiency guns for uniform powder distribution.

Vertical Curing Ovens – Compact yet capable of rapid temperature stabilization, ensuring uniform curing.

Automated Unloading and Packaging Section – Streamlining the post-coating process.

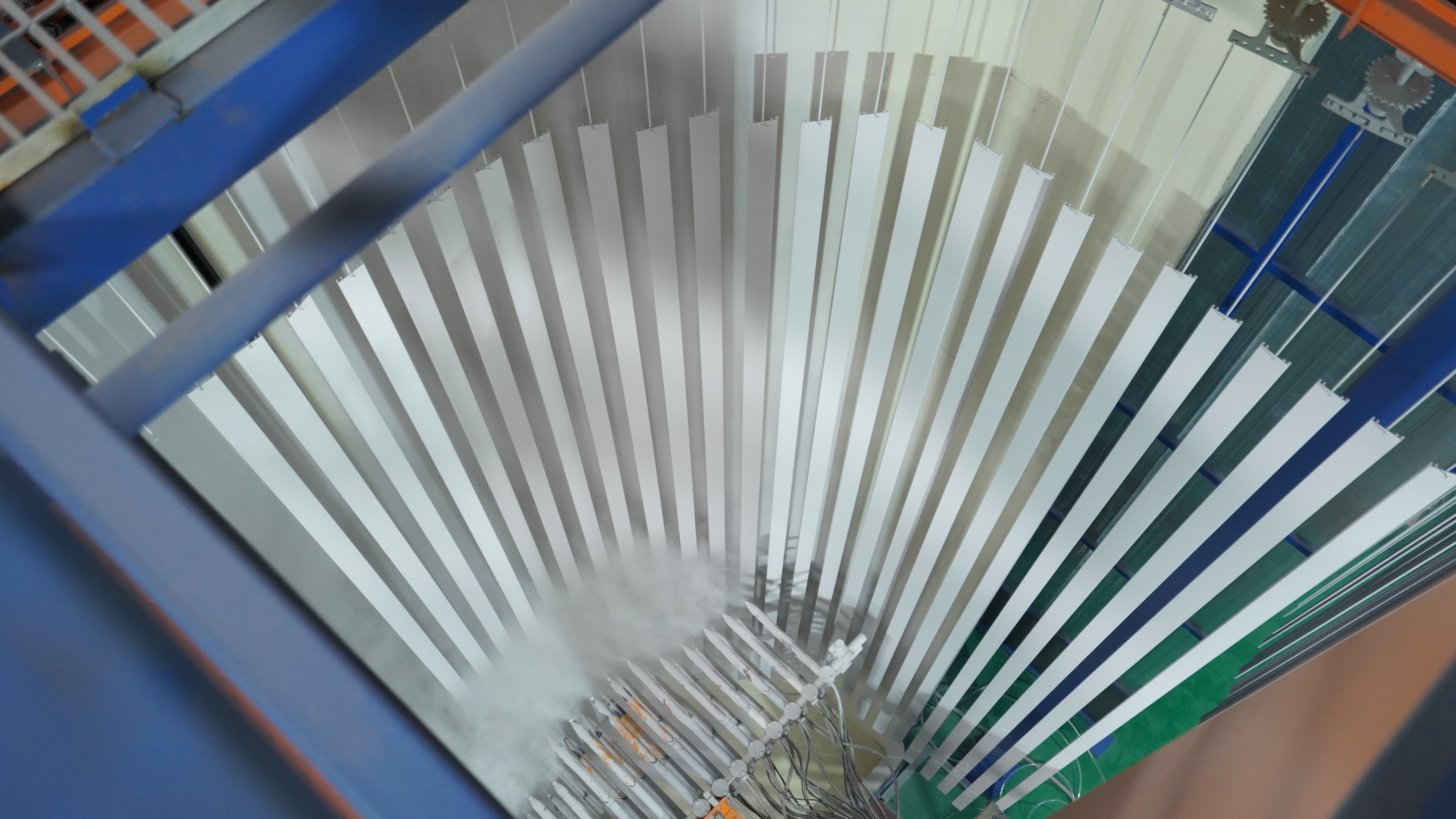

The custom vertical spraying production line installed at Jinniu Aluminium’s factory.

Technical Highlights

1. Space-Saving Vertical Design

Unlike conventional horizontal lines, the vertical layout significantly reduces floor footprint, allowing for more efficient material flow and better space utilization in the factory.

2. High Precision Powder Application

The industrial spraying system utilizes advanced electrostatic guns with adjustable spray parameters, ensuring consistent coating thickness on complex aluminium profile shapes.

3. Advanced Control System

A PLC-based interface allows operators to select coating recipes, monitor production status, and receive real-time maintenance alerts.

4. Energy-Efficient Curing

The curing ovens use an optimized airflow system, reducing power consumption by up to 20% while ensuring uniform heating.

Powder coating in progress on the vertical spraying production line.

Implementation Process

Initial Consultation – Understanding production capacity, aluminium profile dimensions, and coating specifications.

System Design – CAD-based layouts and 3D simulations to optimize workflow.

Manufacturing & Assembly – Precision fabrication of mechanical frames, conveyors, and spraying booths.

On-Site Installation – Integration with existing factory utilities and safety systems.

Training & Commissioning – Hands-on operator training and performance verification before handover.

Finished aluminium profiles being packaged after coating.

Customer Benefits Achieved

Higher Productivity – Increased coating throughput by 35% compared to previous manual processes.

Improved Coating Consistency – Reduced surface defects and rework rates by 20%.

Better Space Utilization – Freed up 25% of factory floor space for additional operations.

Reduced Labor Costs – Automation lowered manpower requirements by 30%.

Enhanced Market Competitiveness – The high-quality finish improved the company’s brand image in both domestic and export markets.

Close-up view of the vertical conveyor section for aluminium profiles.

This custom vertical spraying production line project for Hunan Jinniu Aluminium Co., Ltd. showcases Foshan Happy Technology’s ability to deliver tailored automated aluminium surface finishing solutions that combine space efficiency, coating precision, and operational cost savings. We remain dedicated to providing our clients with cutting-edge aluminium profile coating equipment that meets and exceeds their production goals.![]() Automatic Vertical Powder Coating Production Line.pdf

Automatic Vertical Powder Coating Production Line.pdf