In the competitive world of aluminium door and window manufacturing, achieving a perfect balance between efficiency, quality, and cost control is essential. Sichuan Runhe Doors and Windows Co., Ltd., a respected name in the regional building materials industry, has taken a significant step forward by integrating a vertical spraying line designed and supplied by Foshan Happy Technology.

This installation represents more than just a technical upgrade—it is a transformation in how the company handles surface finishing, enabling them to deliver aluminium doors and windows with superior durability, aesthetics, and market appeal.

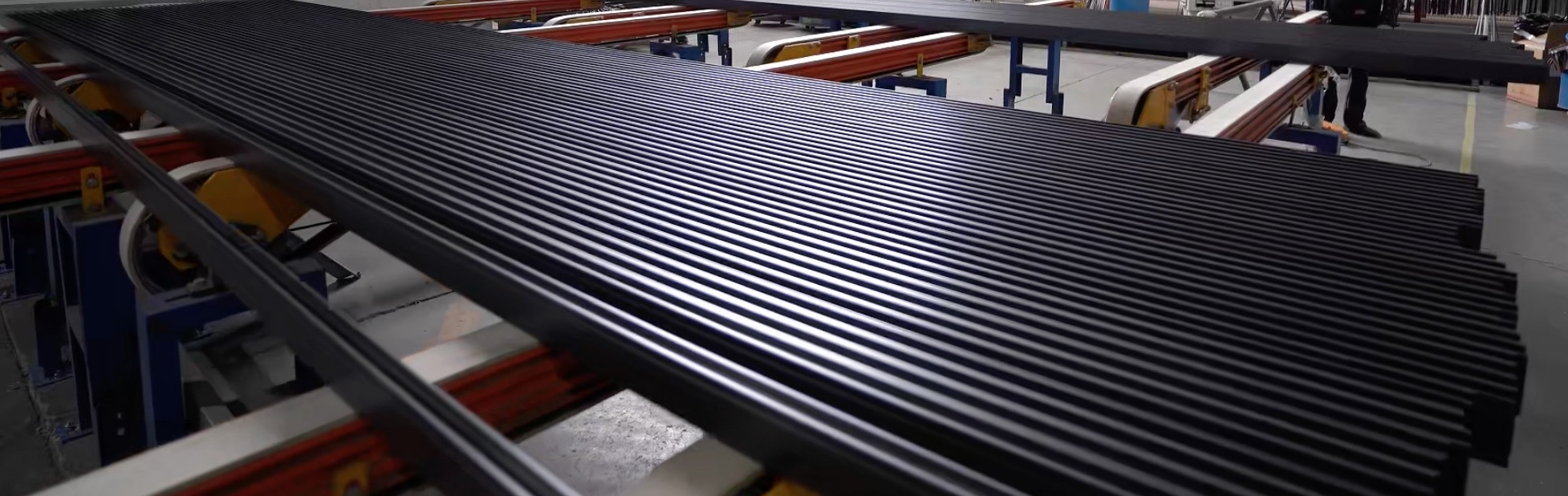

A real-world view of the vertical spraying line in operation at Sichuan Runhe’s facility.

Project Requirements

Consistency – The coating process needed to achieve identical color tone and thickness across all aluminium profiles, regardless of shape or size.

Efficiency – The system had to integrate seamlessly into the existing workflow without causing production bottlenecks.

Space Optimization – The factory required a layout that would fit within limited floor space.

Automation – Reduce reliance on manual spraying to improve consistency and lower operating costs.

Our Custom Engineering Solution

Foshan Happy Technology provided a custom surface finishing system with a vertical spraying line optimized for aluminium door powder coating. The design incorporated:

Automated Loading Conveyor – Handling aluminium profiles with minimal manual intervention.

Multi-Stage Pre-Treatment Tunnel – Removing impurities for maximum coating adhesion.

Enclosed Powder Coating Booths – Equipped with advanced spray guns for uniform application.

Vertical Curing Oven – Saving floor space while ensuring precise curing.

Automated Unloading and Quality Check – Improving throughput and reducing defects.

Powder coating process in progress on the vertical spraying line.

Real-World Performance in the Factory

Since its installation, the vertical spraying line has been running continuously in production at Sichuan Runhe. Observations from the first months of operation include:

30% Higher Output – Compared to the previous manual spraying process.

Improved Quality Control – Color uniformity and coating adhesion reached over 98% acceptance rates.

Reduced Overspray Waste – Enclosed booths improved powder recovery efficiency.

Consistent Curing Results – The vertical oven ensured even heat distribution, reducing rejects.

Freshly coated aluminium doors ready for packaging

Why Vertical Spraying is Ideal for Doors and Windows

1. Space Efficiency

The vertical arrangement allows longer profiles to be coated in a smaller footprint, crucial for factories with limited space.

2. Superior Coating Quality

Even coverage on complex door and window profiles is easier to achieve with vertical suspension and automated gun positioning.

3. Energy Savings

Shorter conveyor paths and optimized heating cycles reduce operational costs.

Full view of the vertical spraying production line inside Sichuan Runhe’s plant.

Customer Feedback

Runhe’s production manager shared:

“The vertical spraying line has completely changed our production flow. Not only can we fulfill orders faster, but the quality of our aluminium doors and windows has improved noticeably. Our customers have also noticed the difference in finish consistency.”

An operator monitoring the automated spraying system in the production line.

The automated aluminium profile spraying line installed at Sichuan Runhe Doors and Windows is a perfect example of how industrial coating solutions for windows and doors can be applied in real-world settings. By combining automation, space efficiency, and precision coating technology, Foshan Happy Technology has helped the client achieve higher productivity, lower costs, and a stronger competitive position in the market.