Powder Coating Accessories Spray Guns: Manual, automatic, or handheld guns for applying powder evenly.

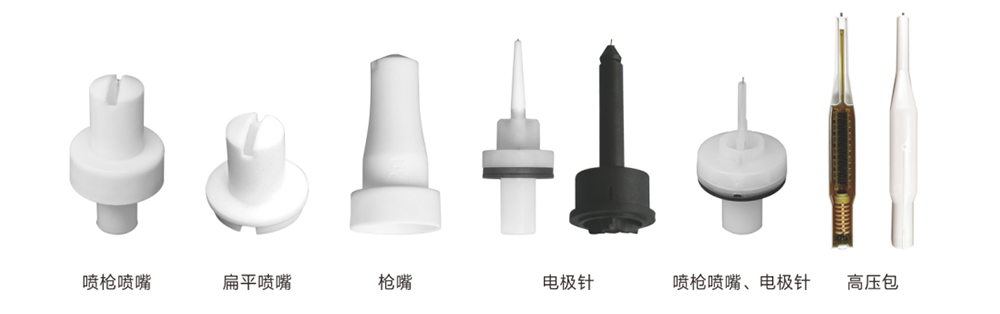

Powder Coating Accessories Nozzles: Different shapes and sizes for specific coating needs (e.g., flat, round, or conical nozzles).

Powder Coating Accessories Replacement Parts: Equipment Accessories Tips, electrodes, and deflectors for spray guns.

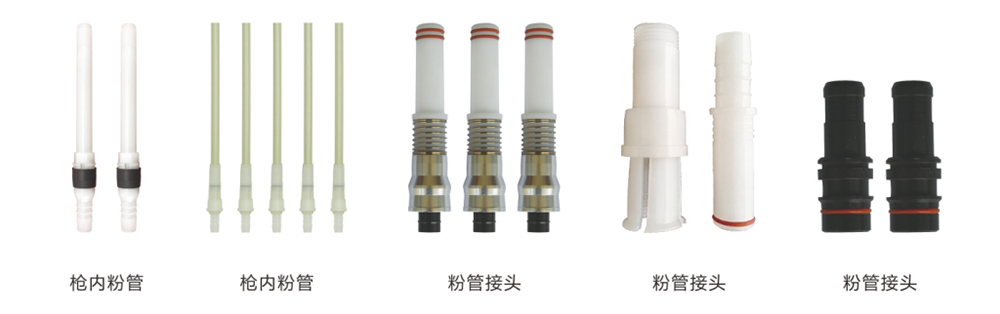

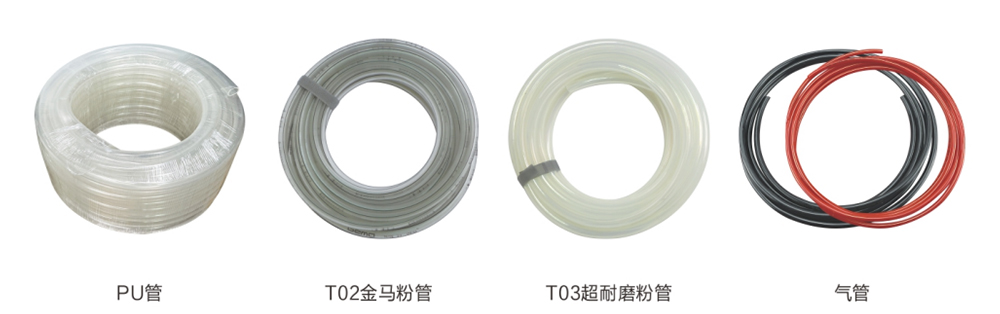

Powder Coating Accessories Powder Delivery Hoses: Equipment Accessories Flexible hoses for transporting powder from the feeder to the spray gun.

Powder Coating Accessories Wear-resistant Tubes: Equipment Accessories Durable tubes for high-volume or abrasive powder applications.

Pump Modules: Equipment Accessories For consistent powder delivery.

Fluidizing Plates: Equipment Accessories Ensure proper powder fluidization in the hopper.

Hopper Accessories: Equipment Accessories Lids, filters, and agitators for powder storage and feeding.

Grounding Cables and Clips: Ensure proper grounding for electrostatic adhesion.

Electrodes: Replaceable electrodes for maintaining consistent electrostatic charge.

Ionizing Bars: For neutralizing static charges on non-conductive surfaces.

Oven Racks and Shelves: Equipment Accessories For holding parts during curing Coating Accessories.

Oven Thermocouples: Equipment Accessories Monitor and control oven temperatures Coating Accessories.

Insulation Kits: Equipment Accessories Improve oven efficiency and heat retention Coating Accessories Powder Accessories.

Blast Cabinets and Media: Coating Equipment For surface preparation (e.g., sandblasting) Coating Accessories Powder Accessories Powder Accessories.

Chemical Pre-Treatment Systems: Coating Equipment For cleaning and etching surfaces Powder Accessories.

Wash Booms and Spray Nozzles: Coating Equipment For part cleaning before coating Powder Accessories.

Cartridge Filters: Coating Equipment For efficient powder recovery in booths Powder Accessories.

Cyclone Separators: Coating Equipment Separate overspray powder from the air Powder Accessories.

Collection Hoppers: Coating Equipment Store recovered powder for reuse Powder Accessories.

Booth Lighting: LED or fluorescent lights for better visibility.

Booth Filters: Replaceable filters for capturing overspray.

Booth Curtains and Seals: Maintain containment and improve airflow.

Powder Purge Kits: For cleaning spray guns and hoses.

Booth Cleaning Kits: Tools for removing powder buildup in booths.

Gun Cleaners: Solvents and brushes for maintaining spray guns.

Respirators and Masks: Protect against inhaling powder particles.

Gloves and Coveralls: Prevent skin contact with powders and chemicals.

Safety Glasses: Protect eyes during spraying and cleaning.

Conveyor Chains and Hooks: For moving parts through the coating process.

Hanger Cleaners: Remove built-up powder from hooks and hangers.

Track Systems: For automated part movement.

Powder Containers: Airtight containers for storing powder.

Sieves and Shakers: For breaking up clumps and ensuring smooth powder flow.

Dispensers: For controlled powder distribution.

Powder Controllers: Regulate powder flow and electrostatic charge.

Temperature Controllers: For precise curing oven management.

Diagnostic Tools: For troubleshooting equipment issues.

Color Change Kits: For quick and efficient color changes.

Powder Mixers: For blending powders to create custom colors or effects.

Touch-up Guns: For small repairs or detailed work.

When selecting accessories, consider factors such as:

The type of powder coating system you use (manual or automatic).

The size and shape of the parts being coated.

The volume of production.

Specific requirements for powder adhesion, curing, and recovery.

Foshan Happy Technology specializes in the design and manufacturing of vertical spraying production lines, horizontal spraying lines, powder coating equipment, and custom industrial coating solutions. Our equipment is suitable for aluminium profiles, doors, windows, and a variety of industrial products. Every project is tailored to meet the client’s unique production requirements, ensuring optimal efficiency, durability, and surface finishing quality.

Yes. We offer custom spraying production line design services based on your available space, production workflow, and capacity goals. Our engineering team provides detailed CAD drawings, 3D layout simulations, and technical consultations. Whether you need a compact vertical spraying system or a large-scale automated powder coating line, we ensure the design integrates seamlessly with your existing operations.

The typical lead time for our spraying production lines is approximately 60–90 days after confirming the technical design and receiving the deposit. For highly customized powder coating equipment or large-scale industrial coating systems, the delivery schedule may vary. We maintain close communication with clients to keep the project on track and ensure timely delivery without compromising quality.

We maintain strict quality control for every spraying production line and industrial coating solution we manufacture. This includes raw material inspections, high-precision fabrication, and detailed assembly checks. Before shipment, each production line undergoes multiple trial runs to test coating quality, efficiency, and system stability. This ensures that every client receives reliable, long-lasting equipment that meets international performance standards.

Foshan Happy Technology exports spraying production lines, powder coating systems, and surface finishing equipment to markets in Asia, the Middle East, South America, Southeast Asia, South Africa, and across China. We provide remote technical support, on-site installation guidance, and after-sales services to ensure smooth operation for international and domestic clients.